As the future of fashion clothing becomes more and more environmentally friendly and brighter, those fabrics that have been damaged and automatically repaired, new fabrics created by deconstructing old fabrics, and fabrics made of natural plant fibers are also becoming more fashionable. Consumers and designers are paying more and more attention. For the spring and summer of 2022, the future fabric textile field will become more technological and “green”. Fabric manufacturers and designers will reawaken those brand new recycled environmentally friendly fabrics through some new technologies. The fashion field is more “green” and richer in technology

This report presents the future through detailed introductions of new regenerated fiber fabrics such as nano “self-repairing” fibers, regenerated cellulose fibers, polylactic acid fibers, man-made microfilament fibers, natural pineapple leaf fibers, and “mycelium” synthetic leather. Recycling technology of “green” new fabrics. These brand-new recycled fabrics have more in-depth research on reducing energy consumption and waste recycling, thereby reducing the impact and destruction of fashion on the earth.

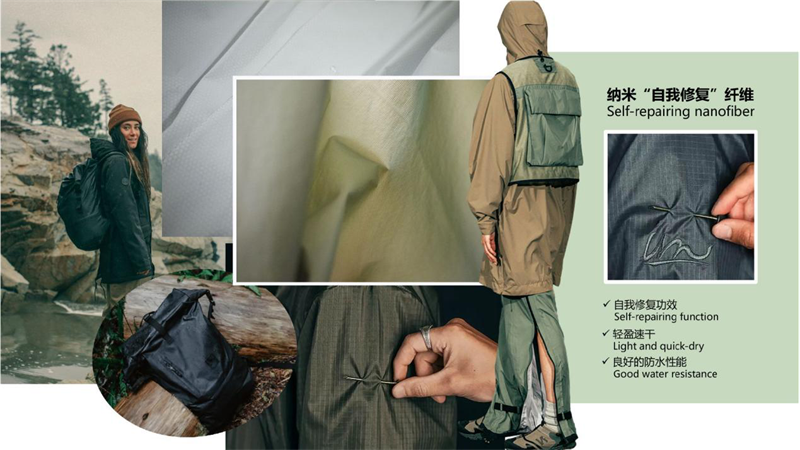

Nano “self-repairing” fiber

Fabric concept: Nano “self-healing” fiber is a new high-tech nano repair material named Nano Cure Tech (automatic repair technology) developed by Pennsylvania State University. It is a PET (with high viscosity, high elasticity and cushioning properties) covered by the surface. Polyethylene terephthalate) coating. The thickness of the pure PET layer is only 125μm (micrometers), while the self-healing layer is only tens of microns, and the thickness can be further compressed as required. The rubbing of the fingers brings friction and heat, and the structure that will be destroyed between the molecules is reconstructed under the action of friction and heat, and the breaks of the fibers will be automatically connected. This fiber material can be stretched to 50 times without damage. The length, because of its “self-repairing” effect, has the characteristics of good light transmission ability, in addition to the use of outdoor clothing materials for men and women, it can even be used in medical fields such as artificial skin.

Fabric functional characteristics: self-repair, light and quick-drying, good waterproof performance

Fabric application: In addition to designing men’s and women’s outdoor vests, coats, assault jackets, cotton clothes and other styles, it can also be used to make outdoor equipment products, such as outdoor backpacks. Reference brand: Imperial Motion.

Regenerated Cellulose Fiber

Fabric concept: Regenerated cellulose fiber is reconstituted by deconstructing discarded old fabrics, and fabric technology company Evrnu uses its engineering technology to develop the first regenerated cellulose fiber denim made from recycled cotton waste. Denim cloth. This technology goes far beyond conventional and standard clothing recycling and utilization, and can deconstruct old cotton fabrics at the molecular level, thereby creating a series of multi-purpose denim denim fabrics that are stronger and more durable than the original fabrics. In addition, the production process of the recyclable regenerated cellulose fiber denim denim fabric consumes very little energy and water, almost no raw materials are used, and the least chemical solvents are used. 98% of the chemical solvents can be recycled and reused.

Functional characteristics of the fabric: no environmental pollution, no toxicity, self-decomposing, more durable.

Fabric application: Regenerated cellulose fiber denim denim cloth can be used to design any denim denim styles and shoes bags for men and women.

Polylactic acid fiber

Fabric concept: Polylactic acid fiber can also be called corn fiber. It is made from corn, wheat, sugar beet and other starch-containing agricultural products. After fermentation, lactic acid is produced, and then polycondensation and melt spinning are made. It has good heat resistance. Polylactic acid fiber is a synthetic fiber whose raw material can be planted and easily planted, and the waste can be naturally degraded in nature. It can be decomposed into carbon dioxide and water under the action of microorganisms in the soil or seawater, and the two can become the raw material of lactic acid-starch through photosynthesis. In addition, when burned, this fiber will not emit poisonous gas and cause no pollution. It is a sustainable ecological fiber. When used in knitted fabrics, it not only has a good feel, but also has anti-ultraviolet rays, low flammability and excellent processing properties.

Fabric functional characteristics: non-toxic, non-polluting, biodegradable, excellent heat resistance, good hand feeling, UV resistance.

Fabric application: This fabric can be used in the R&D and design of various men and women casual knitted sweaters, trousers and T-shirts, and can also be used in sporting goods and sanitary products.

Rayon fiber

Fabric concept: rayon microfilament fiber is a kind of sustainable textile long fiber, which is a kind of artificial silk fiber. This fiber was created by Bolt Threads in northern California and is also called “spider silk” fiber. This kind of “spider silk” fiber is not obtained directly from spiders, but is imitated from the same protein as spider silk webs. Using biological principles, after fermentation, silk protein powder is made, and after dissolution, the required filament fiber is finally extracted through a spool, which is a sustainable and large-scale artificial silk fiber. In addition, this rayon fiber has “excellent” properties in all aspects, such as elasticity, endurance, strength, and flexibility. From the perspective of industrial pollution, this fiber is more green and environmentally friendly.

Functional characteristics of the fabric: Super elasticity and endurance, excellent strength and toughness, and a soft feel.

Fabric application: suitable for R&D and design of dresses, shirts, pants, hats, socks and other styles.

Natural Pineapple Leaf Fiber

Fabric concept: a natural patented protective material made of pineapple leaf fiber, except for its tensile strength similar to flax and jute, it is durable, breathable and flexible. Materials company uses this natural fiber to create different fabric materials and meet the needs of different industries. It can meet the needs of the fashion industry and can also be applied to the design of shoes and bags. In addition, the fabric made of this fiber has been further optimized in terms of wear resistance and water resistance, and it is a very natural and environmentally friendly “green” fabric.

Fabric functional characteristics: green and natural, excellent breathability and flexibility, good wear resistance, waterproof and fireproof.

Fabric application: Suitable for clothing, bags, shoes, and car cushions.

“Mycelium” synthetic leather

Fabric concept: Mylo is a synthetic leather fabric developed by Bolt Threads. This synthetic leather fabric is made of “mycelium” or mushroom roots. Mylo “mycelium” synthetic leather is made of mycelium cultivated by fungus plants under proper conditions, and then cured and tanned. It finally looks and feels very similar to leather. In addition, Mylo “mycelium” synthetic leather has a very wide range of applications. It can be used in any product that replaces leather. Just like natural leather, it can also be dyed, and over time it will have an age-old luster.

Fabric functional characteristics: vegan “mycelium” leather, good hand feeling and strength, stable color and easy care.

Fabric application: Mylo is a leading environmental technology product, which can be used in backpacks, belts, shoes, clothing, etc.

Post time: Apr-28-2021